Fairchild vs Texas Instruments

By now we all have heard about the tremendous challenge that creating the SX-70, it was a big gamble in that many breakthrough inventions had to be accomplished and manufactured for the product to exist. New self-developing film, that just after exposing had to develope itself without any waste, in sunlight, new optics had to be invented and manufactured by Dr. Baker and Dr. Plummer, and yes, new electronics where needed for the “you press the button and the camera does the rest” concept.

So if we roll back to the late 60s, many electronic technologies didn’t exist or they were in their infancy. DIP packaging was still way too thick.

Polaroid was not in the electronics bussiness, so the success of the SX-70 had to be outsourced to different companies. The flash control contract was given to General Electric Co. Then in 1971, when GE dropped out of the IC business, it was issued to Sprague Electric Corp., as well as to Fairchild Semiconductor Corp, of Palo Alto, Calif., and Texas Instruments Inc. of Dallas, Texas. Only Fairchild and Sprague ended up producing flash controllers.

There was also a contract for the motor driver, that went to both Fairchild and TI.

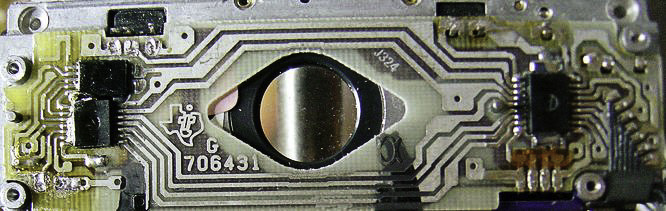

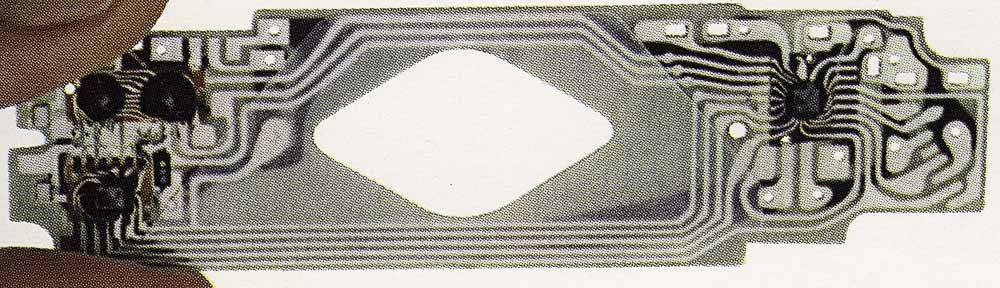

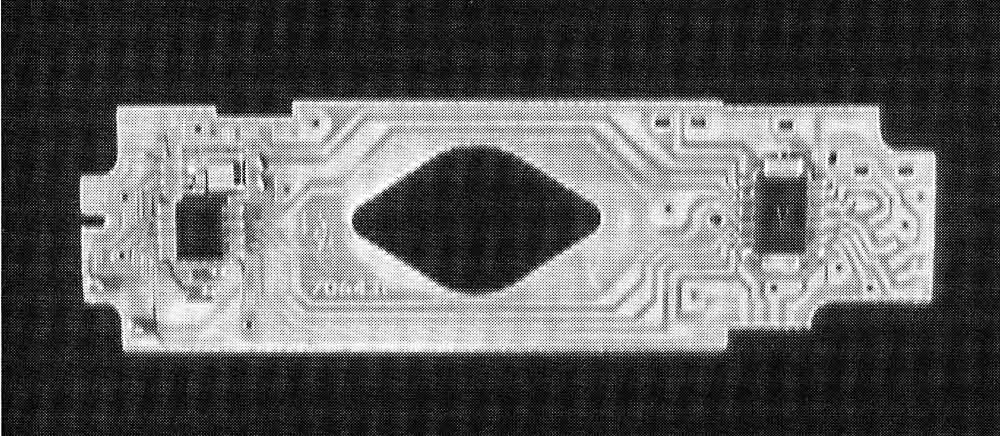

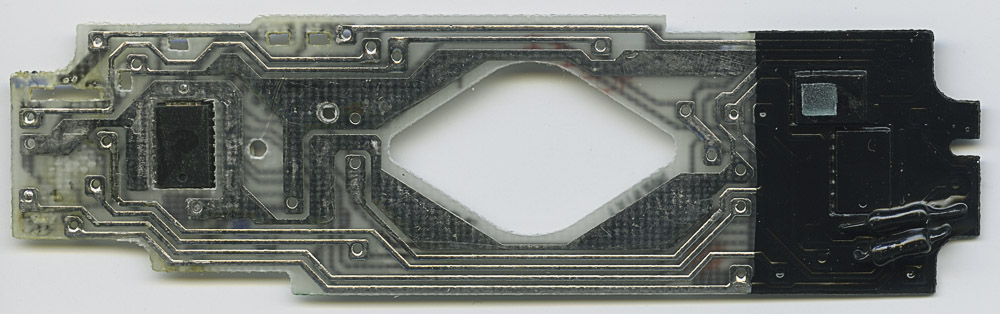

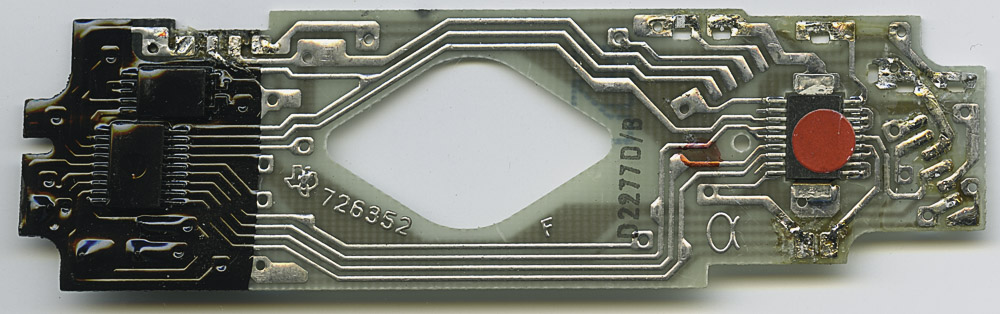

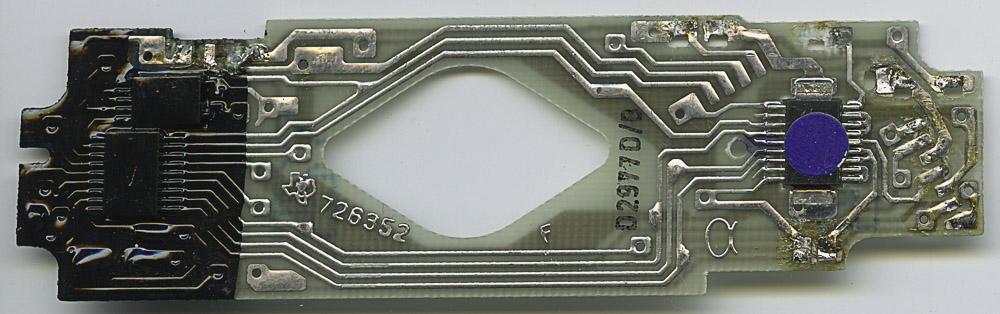

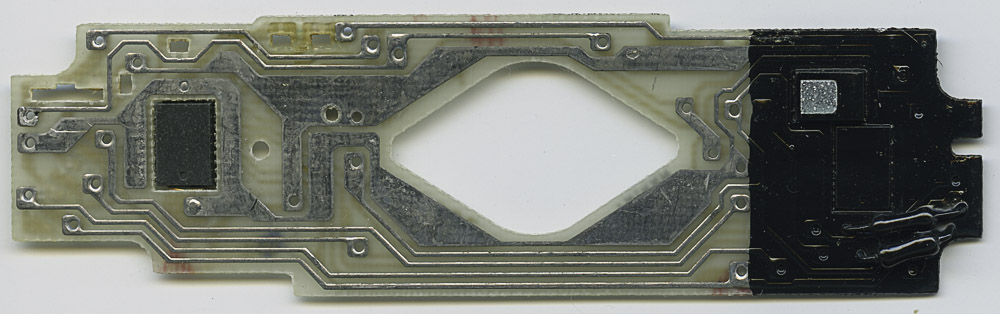

But the greatest challenge was the exposure module, the main PCB, known in Polaroid lingo as ECM (electronic control module).

400 transistors had to be fitted in smal area 96mm x 28mm.

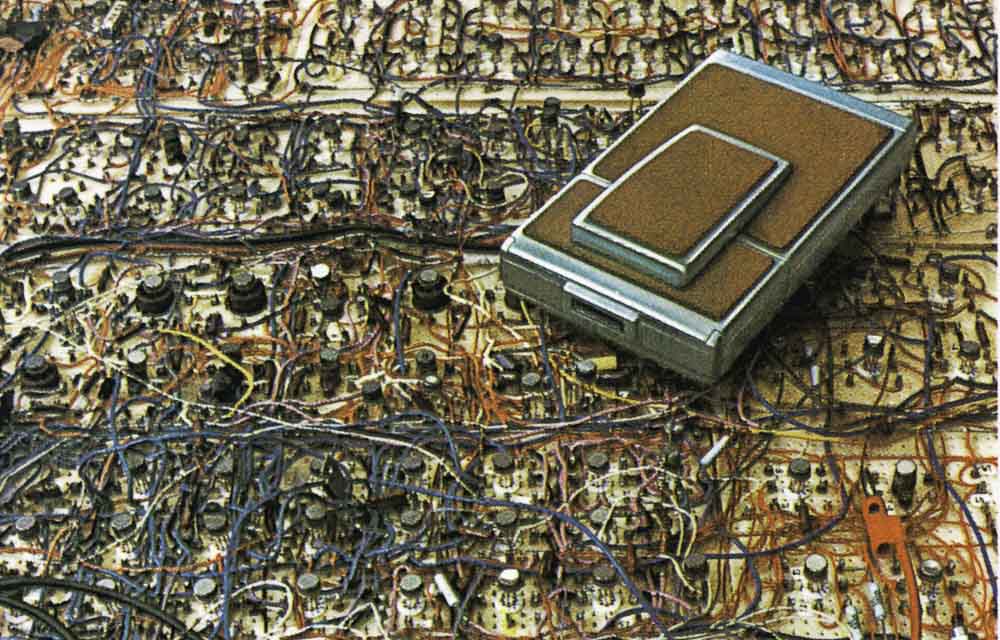

So basically this:

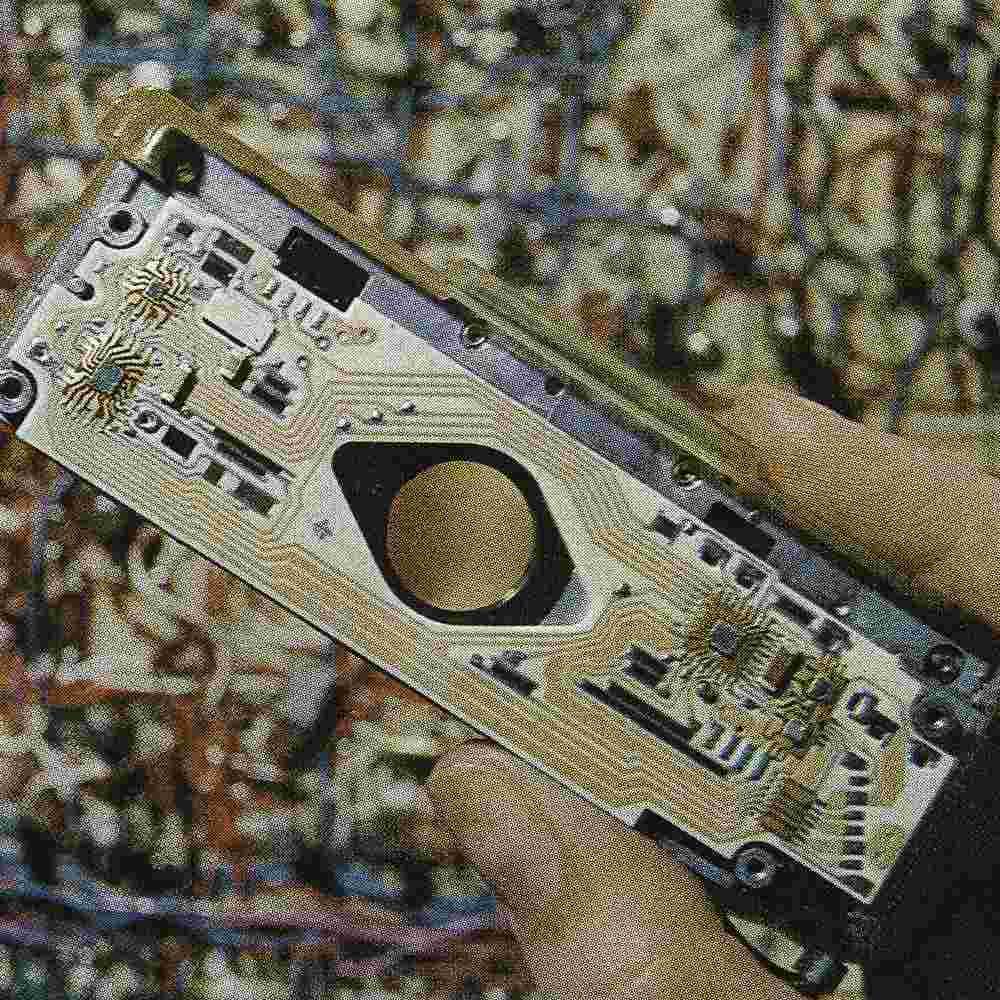

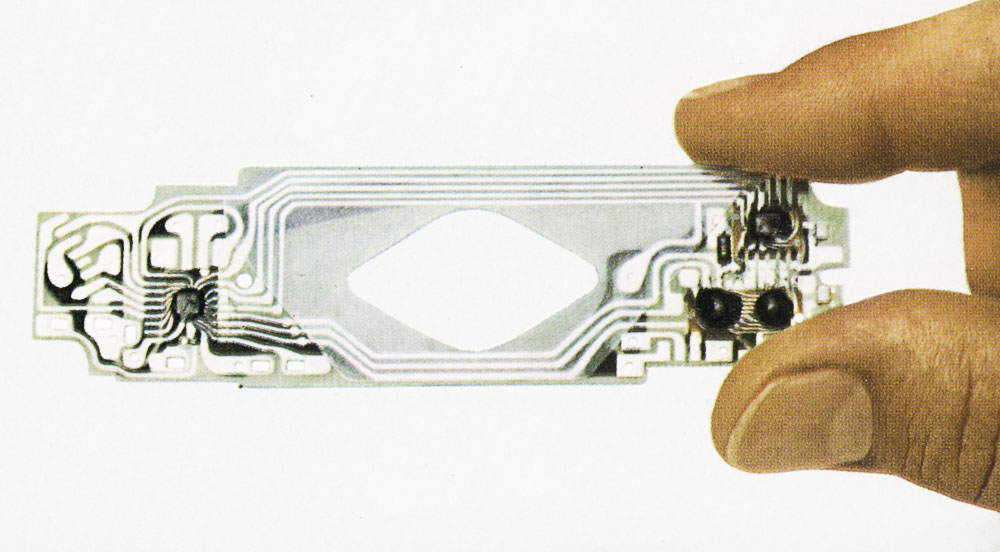

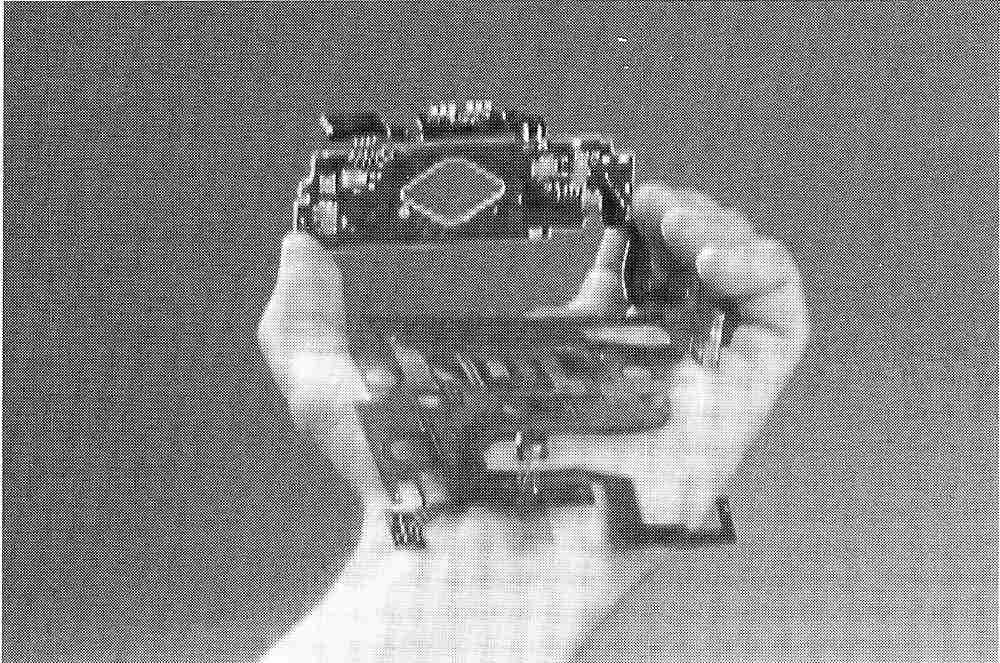

Had to be reduced to this:

Oh, and by the way, all this had to be accomplished for $5.75. That is the equivalent of $36 in today’s money. And yes, in the picture above he is holding the ECM upside down.

Oh, and by the way, all this had to be accomplished for $5.75. That is the equivalent of $36 in today’s money. And yes, in the picture above he is holding the ECM upside down.

I had the privilege to speak on the phone with Pete Carcia, retired engineer, that worked in the project with Dr. Land: You know the camera was essentially, was driven by Dr. Land and any models after that, the SX-70 was kind of his baby, and he wanted a push on integrated circuits and get it in the size. That’s why we have both Fairchild and TI.. So contracts were granted to both Fairchild and Texas Instruments. Let it be noted that TI chairman Patrick Haggerty and Dr. Land were old friends, and had discussed the role of electronics in photography in the past.

Pete recollects:

it was an interesting run, especially the Fairchild’s. We would call them… I don’t know.. young dynamic engineers, thinking they can pull everything off — and I think they got themselves in trouble! (Peter laughs)

“How so?”

well the thing is, when we sent the contracts out okay? They were already experimenting with chips on PC’s.. inboards.. they were in the process of doing that T.I. was not…T.I. was doing ceramics, putting chips on ceramics.

Fairchild saw the opportunity y’know.. to put it on PC boards to make things much cheaper, y’know easier to assemble and everything like that. So they started that process. The trouble is, it was costing them so much money and — I tell a funny story.. they wanted to talk to Polaroid. They wanted to talk to Dr. Land essentially, so I said okay.. and he’ll go.. this just shows you the mind of Dr. Land.

So we had him on a plane, and he says

(Dr.Land) “Peter, do you have any information that I can use?” (Peter) “well I have a book on integrated circuits.

(Land) Give them to me.

*So he starts reading them.. and so when we appear at the meeting.. *

they (Fairchild) says Well Dr.Land, this is costing us so much money

(Land) Well okay, let me tell you what’s wrong!

So he gets up and he’s talking about integrated circuits and what not.. and they were in a state of shock! Y’know that a president of a company how he works with finances

(Land) You solve these problems! You got a job!

They kept trying, but it was costing them too much money, so they dropped out! T.I. had.. they always had on a second level PC boards coming, so they made only some in ceramics to begin with y’know.. and they went over the boards. So that’s kind of the quick overview and that’s why they ended up with T.I. and not Fairchild

But collaboration between Polaroid and the electronics suppliers was a nightmare. Polaroid feared that Kodak was going to enter the instant photography market and wanted to keep the SX-70 project (know as Aladdin) secret. Not even most people within the company knew about it. So little information was given to them,

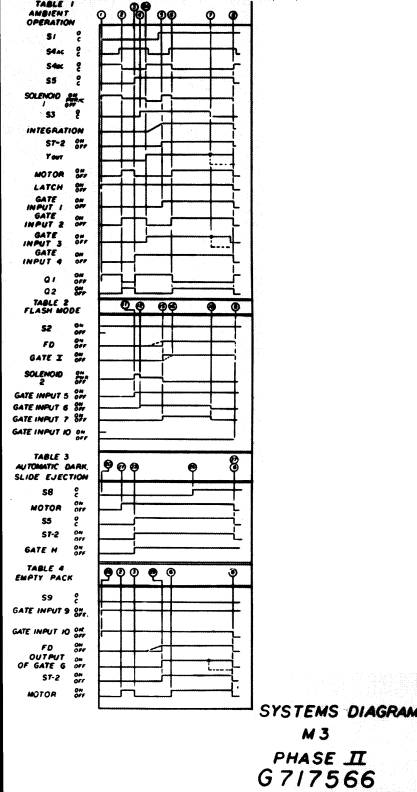

As Gerald Lapidus says in “Behind the lens of the SX-70”: In presenting the design project to its IC suppliers, Polaroid specified a functional block diagram, a timing diagram, and the design of specialized circuits such as the motor and solenoid drivers. Overshadowing the whole design effort was a limit on power and voltage levels, based on the battery design. After determining the maximum power that could be provided by the battery, each portion of the system was given a power budget. Polaroid kept tabs on the power.

We didn’t tell them whether a load on the electronics was from a solenoid or a relay, just that it was an inductive load recalls Seymour Ellin in the 1979 article “The Battle for the SX-70”

Pete Carcia recalls when I asked him if it was it true that T.I. or Fairchild made the modifications then you tested it on the cameras and you got back to them? At the beginning, they didn’t get to see the camera at the beginning?

No, no.. all they knew was this was the PC board they were suppose to build, and we did not show them the camera.. the camera was not shown to them. They were told what we needed in terms of signals..

Now, of course.. as we were getting along and we were more confident with the film and stuff we changed the relationship with T.I. we brought them in tighter and tighter as things progressed, but in the beginning they didn’t have the foggiest idea..

(Chuckles)

but they knew it was a camera.. at least?

yeah oh yeah! They knew it was camera. They just didn’t understand what was going on. And I’m sure, as we were hanging around.. T.I. and Fairchild people aren’t dummies they knew something of picture taken, but we didn’t say anything!

Did they have the outline of the PCB or something?

we had an outline of what we wanted, and essentially, where we wanted chips to be put, we had to put constrain on them, behind the shutter.. y’know it has that front shutter. We gave them those dimensions we gave them where they can go in terms of getting close to the lens. They had to stay within that box, and we defined that for them ahead of time.

The closer we were getting to a definitive camera and solving all the problems we would release to them on a slower basis, and they had to sign a paper they wouldn’t say anything

One of the engineers recalls, that if given an NDA, with access to the hardware they could have done the work in two weeks, but Polaroid insisted on secrecy. TI finally sent to two engineers to Cambridge.

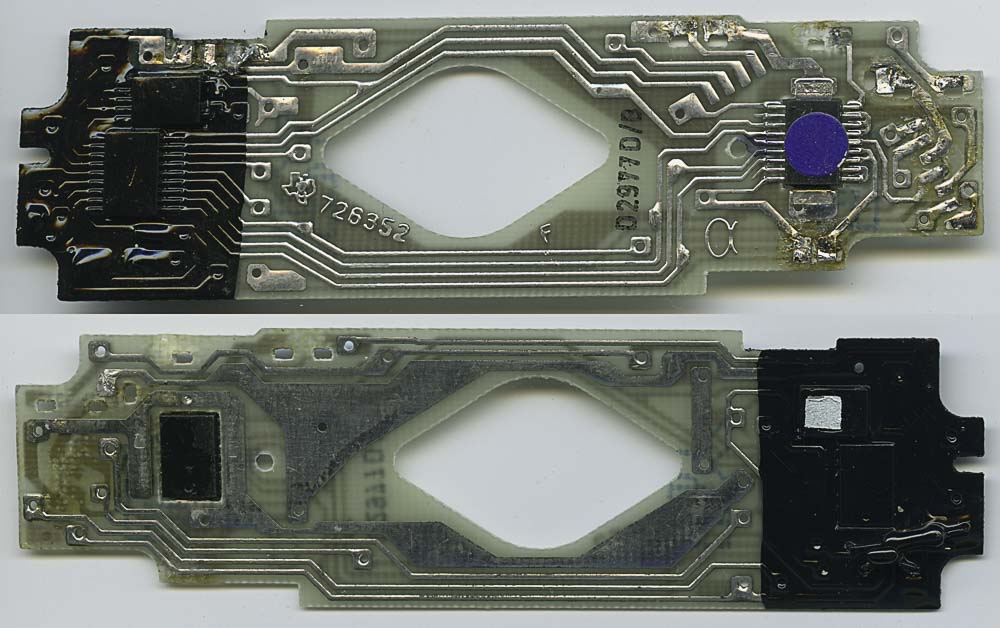

So initially there were ceramic PCBs. Problem with these was a 1 in a hundred yield, and its fragility, not to mention its outrageous cost, each about $100, but of course as the shareholder’s meeting was closing up they needed something to use, a few working cameras and spares. The public was not to touch the cameras on that occasion.

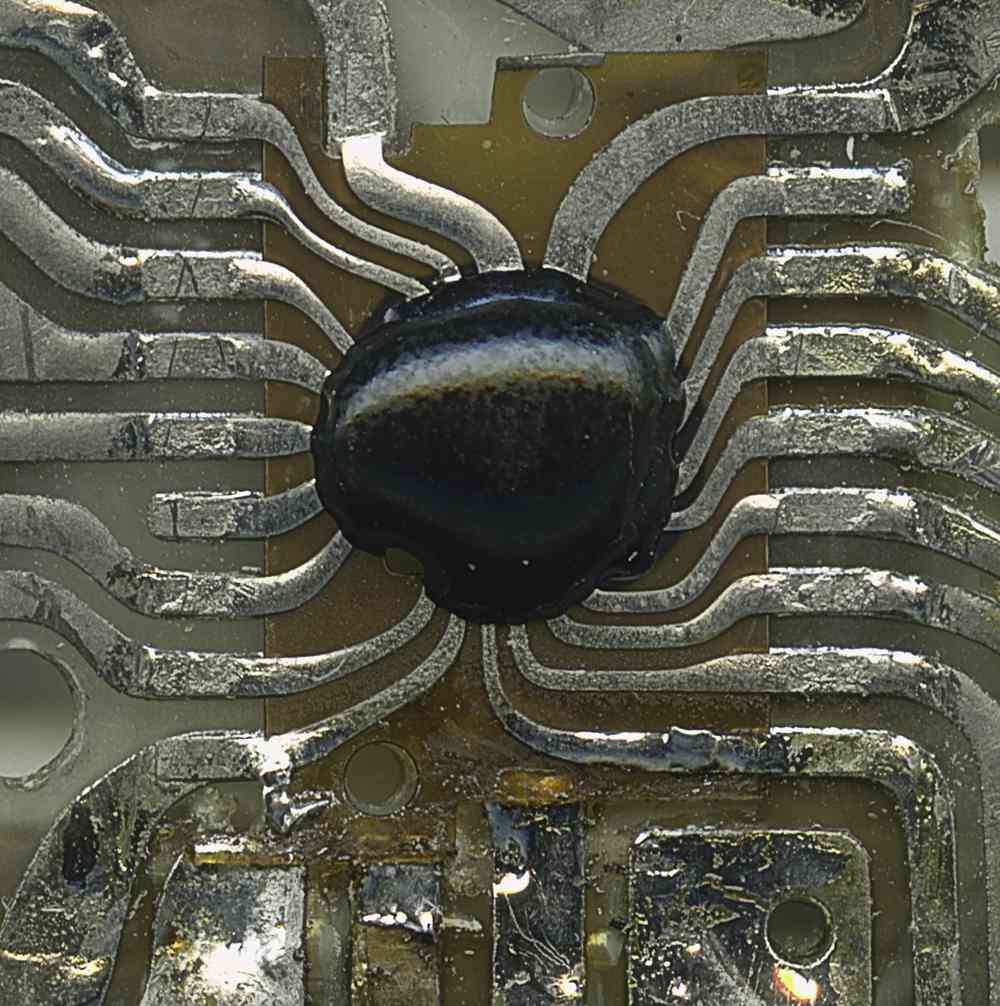

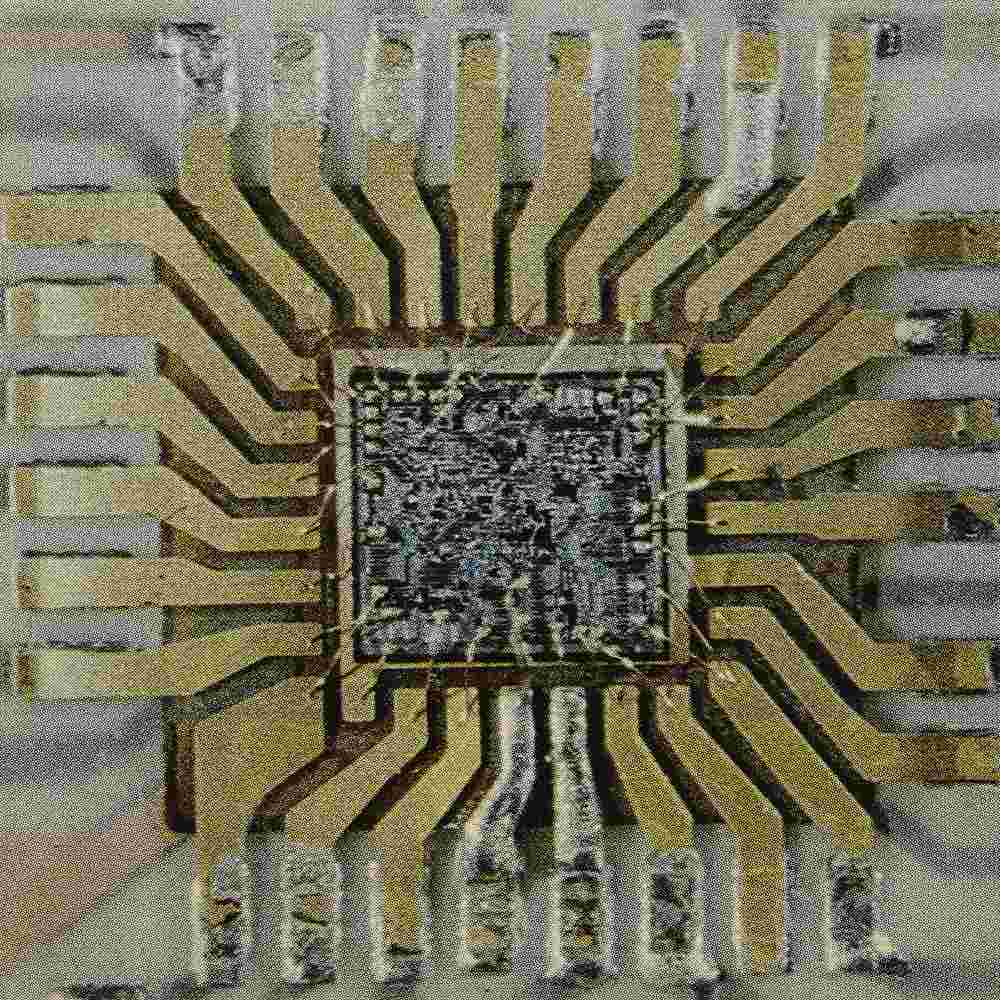

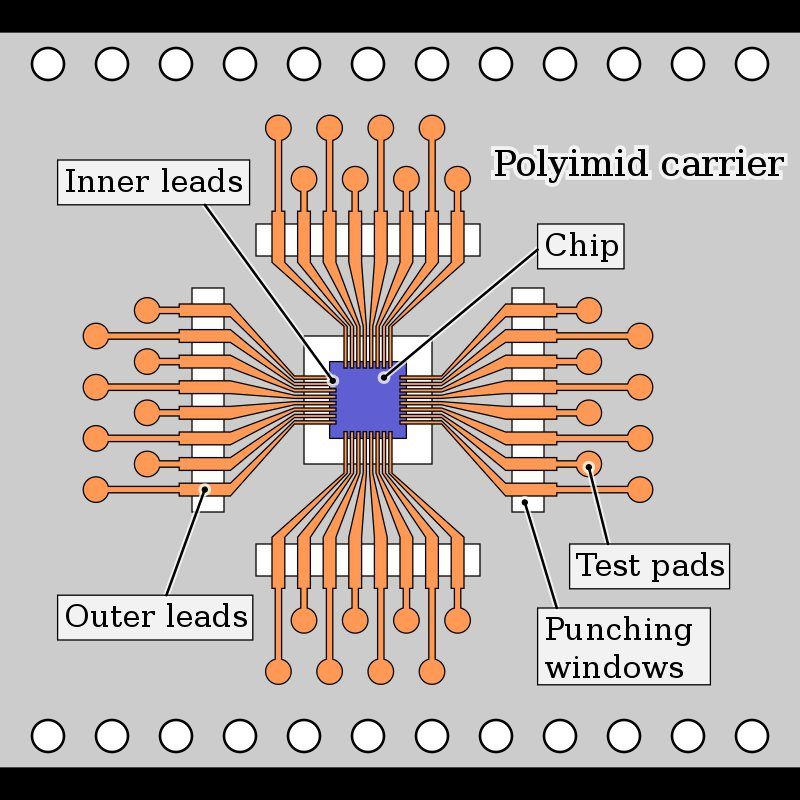

Frank Perrino, a product manager at Fairchild invented beam tape packaging (BTP), a forerunner of what is now called tape automated bonding (TAB). After investigating BTP, he told Fairchild and Polaroid management, “If we don’t do it this way, it’s not worth doing.” Both agreed.

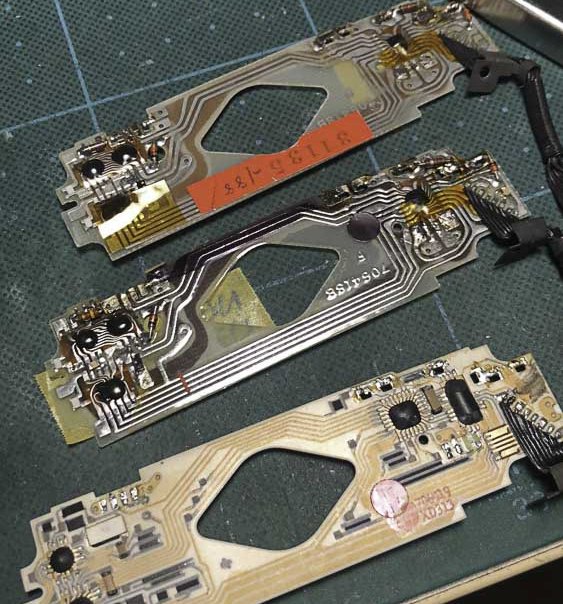

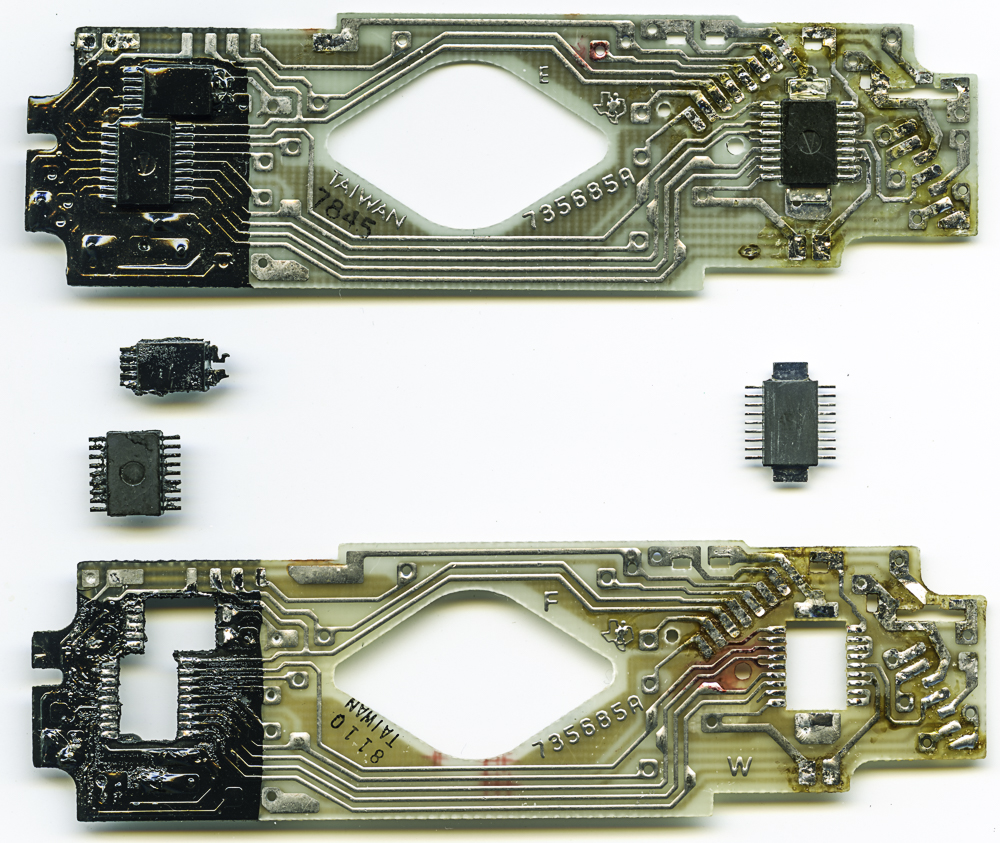

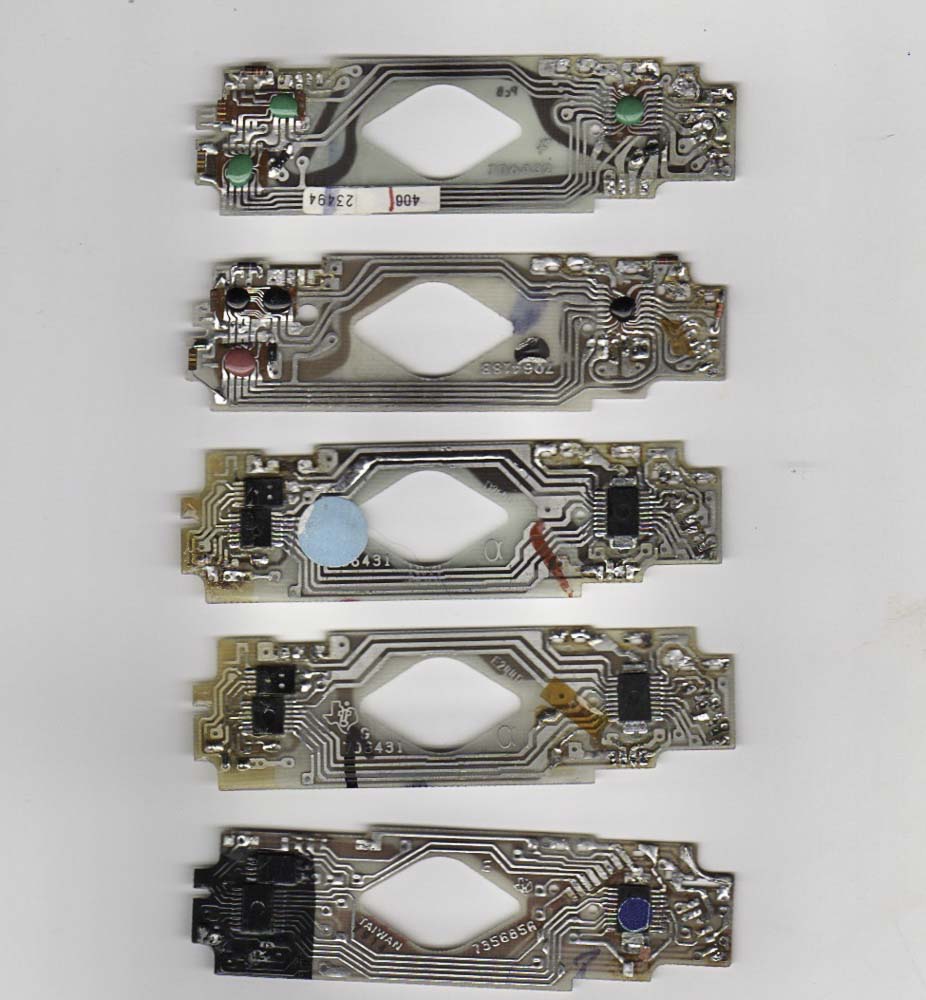

You can clearly see the tape in this Fairchild PCB.

BTP employed reels of film with copper traces laminated on it around preexisting holes. Chips with bumps of solder on their pads were centered under the holes and bonded to the overhanging copper leadframes. Individual die/film modules were then encapsulated, tested, clipped off the reel, and soldered to the circuit board.

Picture from LIFE MAGAZINE.

From Wikipedia.

From Wikipedia.

![]()

By Khpsoi - Own work, CC BY-SA 4.0

The cameras used in the unveiling had Fairchild electronics. A $19M contract was awarded. And all seemed lost to TI.

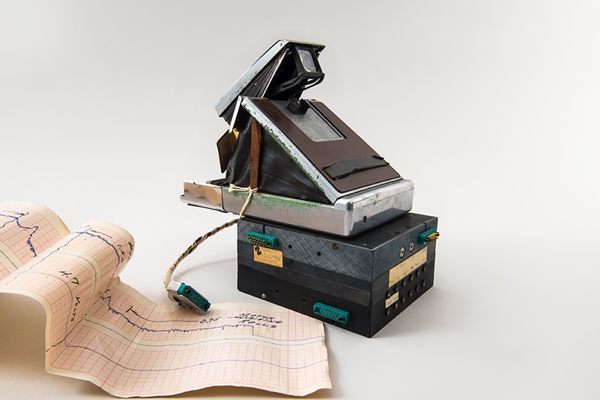

Early prototype to test electronics courtesy of MIT museum.

But remember that TI CEO Haggerty was a friend of Dr. Land? It was a matter of pride for him, so he assigned more than half a million dollars to the project and code-named it Alpha (yes Alpha, that is why there are early TI PCBs that have the ALPHA symbol but are not in alpha cameras). They had a meeting with Polaroid that finally agreed to less demanding requirements with the leadership of Henri Jarrat from TI. For instance things like the 20 seconds timeout of the camera in dark enviroments was reduced to 10 seconds.

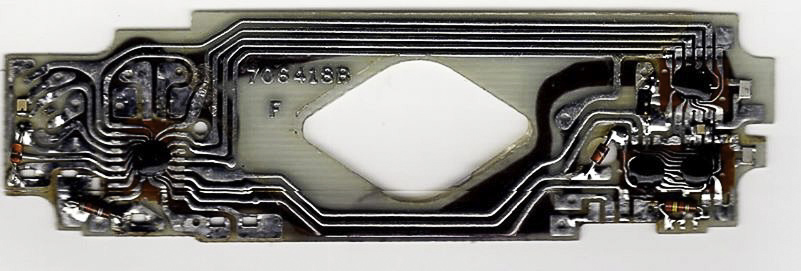

But even so the components where to thick, and a clever method was devised to make them less bulky.

Components were using the just invented surface mounted technique, in mini-DIP footprint, which is basically known as SOT (small outline transistors) or SOIC.

Photo courtesy of the Polaroid Retirees Association.

TI began producing the Project Alpha boards in quantity in mid-1973 with a quoted price to Polaroid of about $4.10 a unit—well below the $5.75 target. Fairchild president Hogan: At the time, it cost us $10. We really believed we could get it to $6, but when TI bombed the price down to two-thirds of the target price, we just had to drop out.

So in the end TI won the contract. All PCBs or ECMs from that point where manufactured by TI, but Fairchild still kept some of the other electronics. Fairchild engineers felt that Polaroid had been unfair to the them.

To read more: “The Battle for the SX-70 electronics”, IEEE SPECTRUM, May 1989,

“Behind the lens of the SX-70,” by Gerald Lapidus, IEEE Spectrum (December 1973, pp. 76-83).

“Polaroid’s Big Gamble on Small Cameras” (Time, June 26,1972, pp. 80-82)

“If you are able to state a problem, it can be solved” (Life, October 27, 1972, p. 48).

The Instant Image: Edwin Land and the Polaroid Experience by Mark Olshaker (Stein & Day, New York, 1978).

Frank Perrino’s version of tape automated bonding is described in U.S. Patent #3,868,724, “Multi-layer connecting structures for packaging semiconductor

1973 WESCON meeting (Pezzolo, D.E., “Camera electronics, a new approach,” session 32)

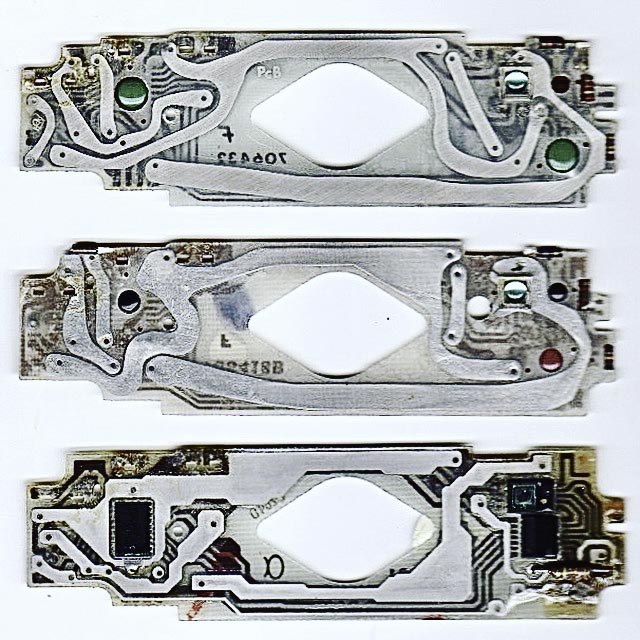

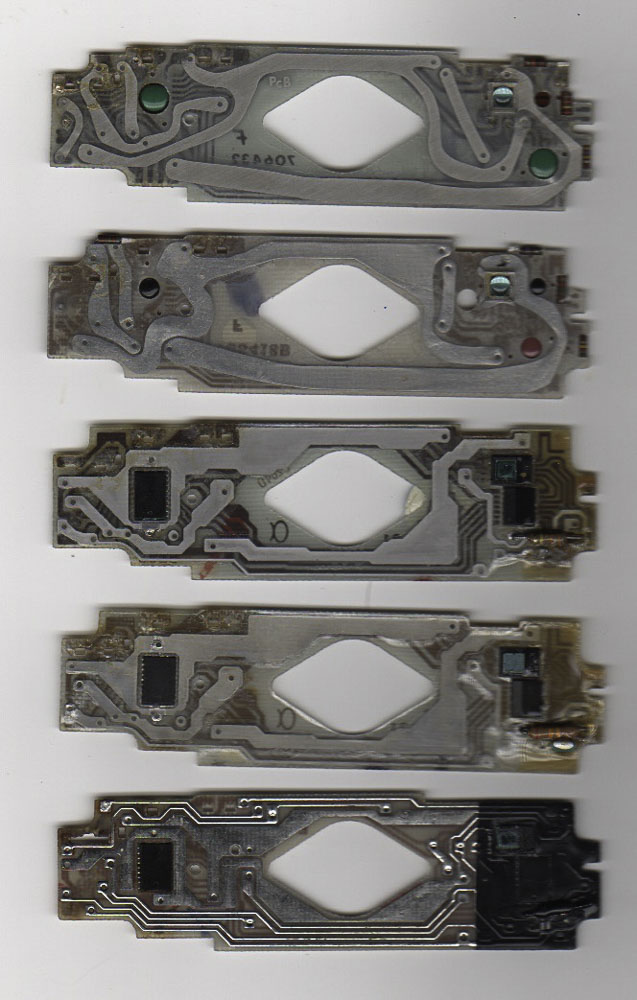

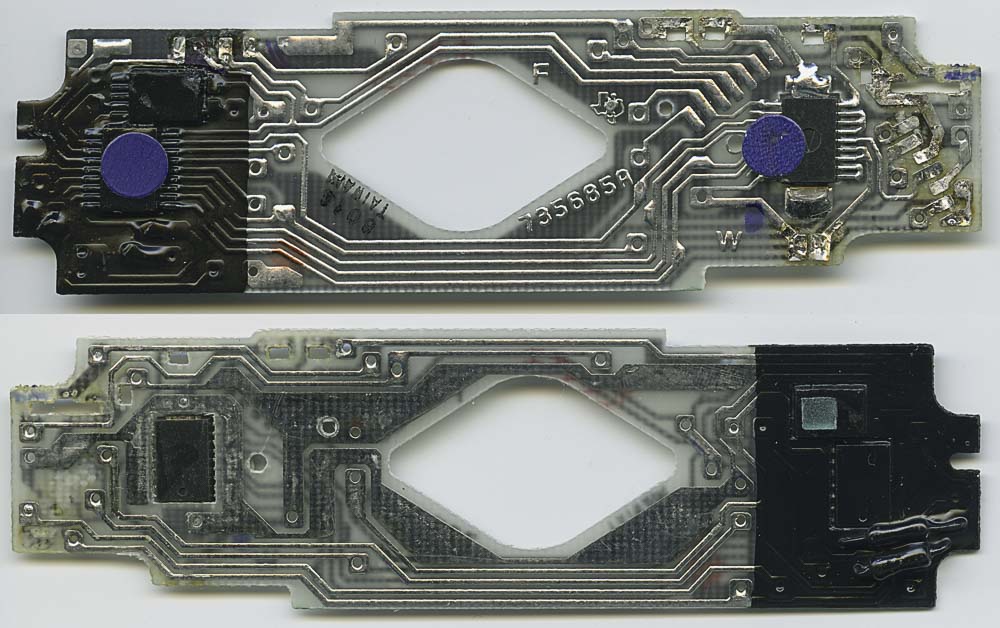

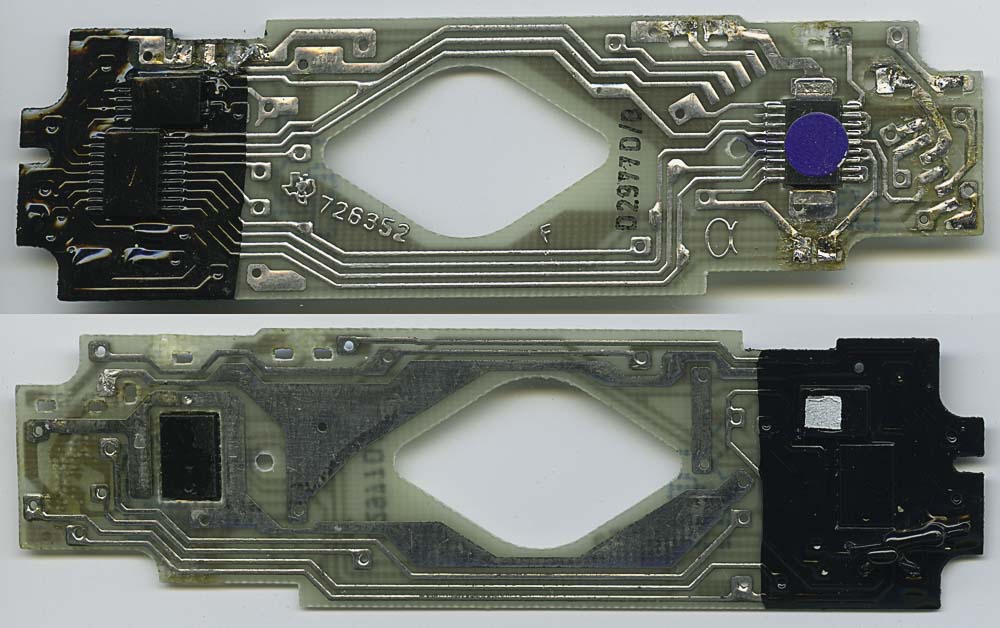

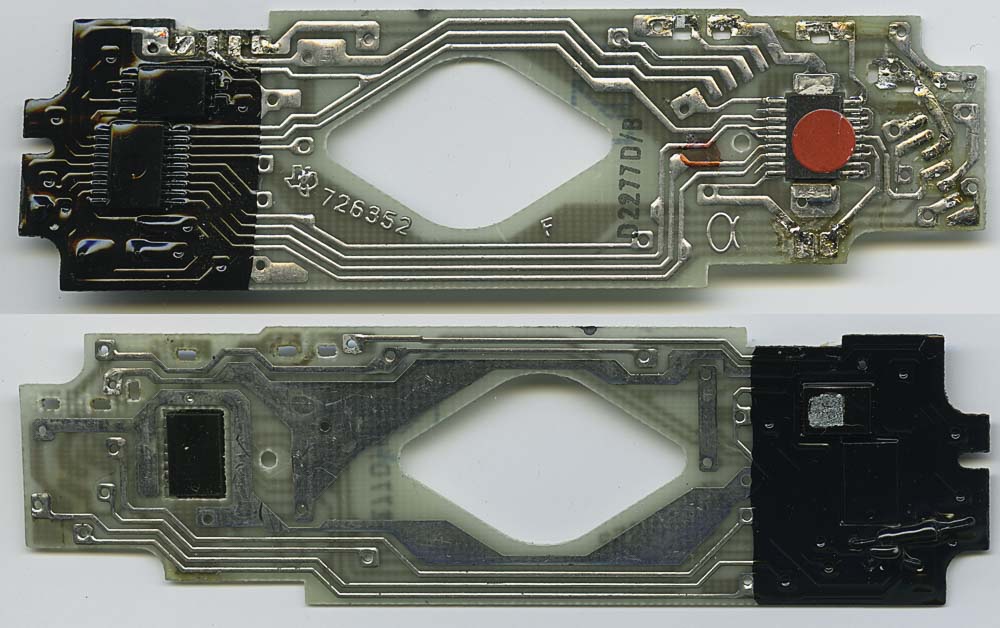

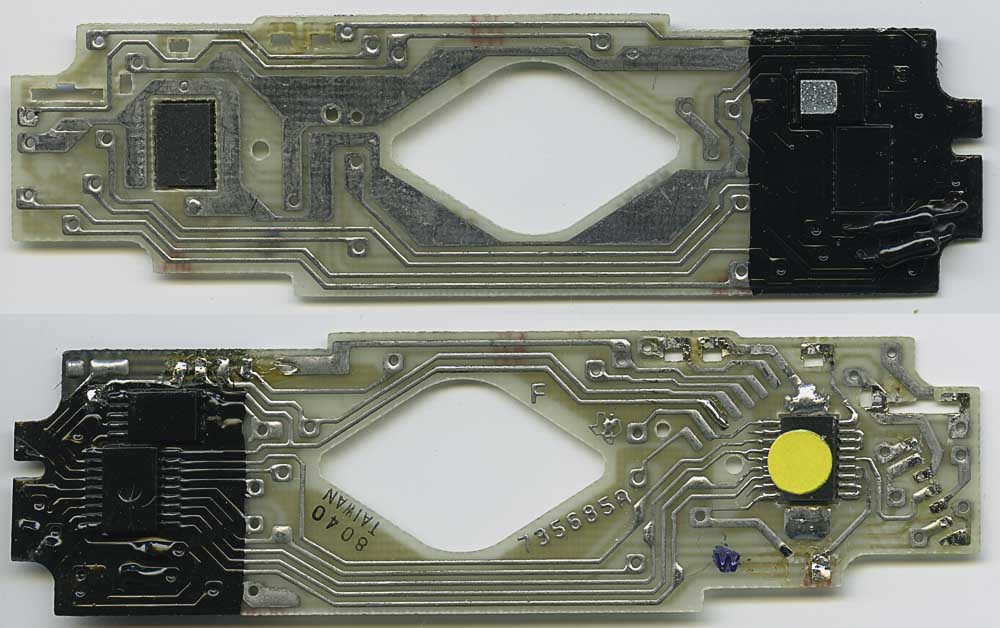

This are pictures of different SX70 ECMs no more text from here.

Comments